This complexity is driven by different factors, including but not limited to common activity for multi-products and a greater number of supportive activities for the production. This means that for every hour of work the marketing agency performs, it will incur $20 in overhead costs. The best way to predict your overhead costs is to track these costs on a monthly what is predetermined overhead rate basis.

Can be Used in the Budgeting Process

- The management can estimate its overhead costs to be $7,500 and include them in the total bid price.

- Direct costs are expenses traced to specific products like raw materials or direct labor.

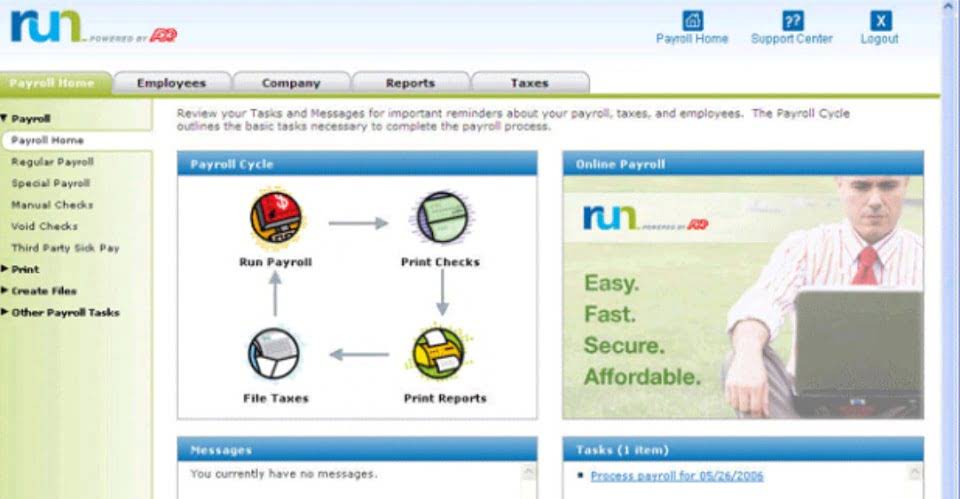

- Implementing predetermined overhead rates involves key steps for accurate cost allocation.

- Moreover, regularly reviewing and adjusting the predetermined overhead rate can help businesses adapt to changes in their cost structure or operations, ensuring they remain competitive and profitable.

- You can calculate this rate by dividing the estimated manufacturing overhead costs for the period by the estimated number of units within the allocation base.

- Features like automated categorization and reporting provide real-time visibility into overhead costs.

Other overhead examples include indirect labor, such as factory supervisors or maintenance staff, and indirect materials like cleaning supplies. These expenses are grouped as “overhead” because directly assigning them to individual units would be impractical. Their benefit extends to the overall production process rather than to a single product unit. Learn how businesses utilize an estimated rate to consistently allocate indirect costs to products, enabling accurate costing and financial insights. Predetermined overhead rates are also used in the budgeting process of a business. As discussed above, a business must wait until the end of a period to know the actual performance in terms of overheads incurred.

Unit Converter

A predetermined overhead rate is an allocation rate that is used to apply the estimated cost of manufacturing overhead to cost retained earnings objects for a specific reporting period. This rate is frequently used to assist in closing the books more quickly, since it avoids the compilation of actual manufacturing overhead costs as part of the period-end closing process. However, the difference between the actual and estimated amounts of overhead must be reconciled at least at the end of each fiscal year. While predetermined overhead rates are widely used and needed for businesses, they may have some limitations.

Calculation of Predetermined Overhead and Total Cost under Traditional Allocation

- The estimated activity base can be direct labor hours, machine hours, or any other cost driver relevant to the business.

- This comparison can be used to monitor or predict expenses for the next project (or fiscal year).

- Therefore, a company should choose the basis for its predetermined overhead rates carefully after considering all the factors.

- To ensure that the company is profitable, an additional cost is added and the price is modified as necessary.

- It is equal to the estimate overhead divided by the estimate production quantity.

- Its simplicity and precision make it essential for effective financial management and operational planning.

This can be estimated using several techniques such as break-even analysis and margin of safety or for more established businesses, this can be estimated using previous period’s or historical level of activity. Instead of using the numbers of units to be produced, the business may also choose another activity base such as labor hours or machine hours that are needed to meet the estimated level of activity. A predetermined overhead rate is a rate used to apply manufacturing overhead to products or job orders and is established before a period begins. This rate is calculated by dividing the estimated manufacturing overhead cost for a period by the estimated total units in the allocation base for that same period. Therefore, in simple terms, the POHR formula can be said to be a metric for an estimated rate of the cost of manufacturing a product over a specific period of time.

Knowing the total and component costs of the product is necessary for price setting and for measuring the efficiency and effectiveness of the organization. Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than https://prime.med.br/fedex-office-huntersville-nc-9818-gilead-rd-28078/ direct material, direct labor, or selling and administrative costs. Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing..